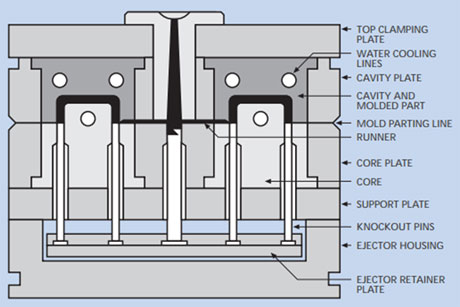

An ejection system in injection molding is used to push the final sample out of the mold. They are used powerfully to push solid parts out of molds, usually made of high-quality steel. There are various types of injector systems. It relates to the shape, structure, and plastic properties of the product. Generally have ejector pin, jacking tube, stripper plate, ejector block, square ejector, and so on.

How does the ejection system work?

1. After the die opening is completed, the rod of the injection molding machine will push the roof. The pop-up board will move forward. The ejector guide pin will guide those moves.

2. The ejector pin is fixed between the two roof plates in order to move forward and push the product out of the mold.

3. After receiving the product, the rod of the injection molding machine will move backward. The spring of the reset pin will push the roof back. The spring and die will guide the ejector back to this position.

The selection of the type of ejection:

The design of the ejector mechanism directly affects the quality of plastic products in injection mold structure. If the design is not good, plastic parts will produce a series of defects, such as plastic parts warp, deformation, crack, and white phenomenon. The determination of the type of pop-up is the most important part of the design of the pop-up. The type and number of ejectors and the location of ejectors are optimized based on ejector forces and ejector resistance.

1. The ejector rob is the simplest and most common form of the ejector mechanism. It is widely used in production because of its convenient manufacture and processing. However, the circular ejection area is relatively small, which tends to lead to stress concentration, product wear, and product deformation. In tubular box products with small drawing Angle and high resistance, try to avoid using them. When the shaft is relatively slender, it is usually provided with a stepped thimble to enhance rigidity and avoid bending and breaking.

2. Top pipe, also known as a tube or department pin, is applicable to ring, tube, or center hole products. It is rolled out evenly throughout the cycle, without deforming the product or easily leaving a clear top mark, thus increasing the concentricity of the product. However, the use of coarse and fine products around the product should be avoided to avoid damage due to processing difficulties and reduced strength.

3. Striper plate is suitable for thin products with various containers, boxes, pipes, and thin strips with center holes. It has a smooth and even popup effect, and the play force, will not leave any trace. Normally, in order to prevent the push plate from being pushed down during production or demolding, a fixed connection will be used, but the push plate will not be fixed as long as the guidepost is long enough to strictly control the ejection travel.

The ejection system is the last part of the injection molding process and the step to make the product fall off in the mold. Even though the product has been molded in the mold cavity, the product will still be defective due to the design defects of the ejection system, such as the drag marks caused by the improper design or misalignment of the ejection system, resulting in scratches when ejection from the mold.