Injection molding defects can often result from the material itself or how the manufacturer stores and processes the material prior to the production process. These defects range from minor aesthetic problems to reduced strength of finished components. Depending on the intended use of the affected product, serious safety concerns can also arise.

Discoloration

Discoloration or “color stripe” occurs when the color of the molded part is different from the expected color. Usually, discoloration is limited to a local area on a molded part or a few stripes of unusual color. This defect usually affects the appearance of the part without reducing its strength.

Causes and solutions

A common cause of discoloration is residual particles in the hopper or residual resins in the nozzle or mold (from the previous production). Poor thermal stability of coloring agent or improper mixing of the masterbatch is another potential cause. The following precautions can be taken to limit the risk of discoloration in injection molded products:

- Ensure that workers properly clean the hopper, nozzle, and mold between production runs to eliminate any residual particles or substrates

- Consider using a cleaner to remove excess color from the machine

- Ensure that you or your supplier are using colorants with sufficient thermal stability

- Ensure that the color master is evenly mixed to achieve a consistent color output

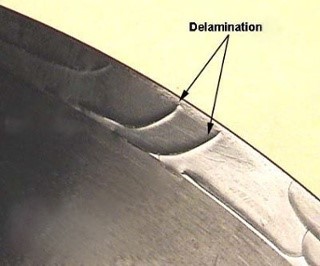

Delamination

If a thin layer on the surface of a molded part is found to easily separate or peel off the underlying material, you will see a forming defect called lamination. Lamination is a defect characterized by peeling of the surface layer, similar to what you usually find on flake mica. This is often considered a relatively serious defect because it reduces the strength of the component.

Causes and solutions

The most common cause of lamination is the contamination of resin particles or other base materials with foreign matter. When the two materials do not combine properly, lamellar separation occurs. For example, you can combine a common base plastic such as acrylonitrile butadiene styrene (ABS) with an incompatible plastic such as polypropylene (PP). If you intend to use parts for safety-critical purposes, the loss of material strength can be very dangerous.

In addition to the material in the hopper, the contaminant may be any excess release agent covering the mold to facilitate component separation. Due to improper drying before use, too much moisture on the material will also lead to lamination. If it is found that layering affects molded parts, please consider the following corrective actions to prevent recurrence:

- If excessive moisture is present, raise the mold temperature or pre-dry the material appropriately

- Ensure workers properly store and dispose of resin particles or base materials to prevent contamination

- Consider redesigning the die, with emphasis on the injection nozzle, to reduce the dependence on the release agent