Our Manufacturing Capabilities

Our vision is to become a leader in the custom processing field.

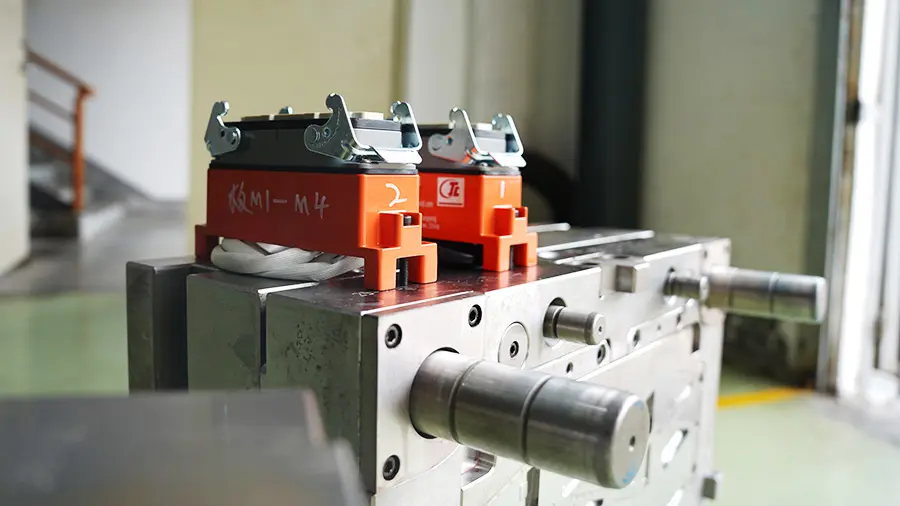

Injection molding service meets your stringent criteria & FDA requirements while achieving your plastic prototypes intent and finishing your on-demand, affordable, high-quality molded parts within days.

By bonding multiple materials together, our overmolding process improves grip, durability, and aesthetics. It’s perfect for soft-touch handles, protective casings, and multi-material assemblies, enhancing both functionality and user experience.

Insert molding enhances part strength by integrating metal or other materials directly into plastic components. This method is ideal for electrical connectors, automotive parts.

By bonding multiple materials together, our overmolding process improves grip, durability, and aesthetics. It’s perfect for soft-touch handles, protective casings, and multi-material assemblies, enhancing both functionality and user experience.

RJC mold can meet all needs for your tool and mold manufacturing for the features suitable for many different kinds of substrates, highly accurate and repeatable, fast turnaround, low investment in tooling or preparation costs, and highly accurate and repeatable.

Rjcmold provides aluminum mold and steel mold for rapid tooling according to the needs of customers.

It can hand over the parts of your designated materials within 2-5 weeks.

Mold and Product Engineering Support

Our engineering team provides comprehensive DFM reports and mold flow analysis to optimize part design, improve mold manufacturability, accelerate lead times, and ensure stable high-volume production.

We select the appropriate mold materials based on product requirements and design precise molds, including those with complex structures and custom features.

Why choose us?

A full-service company supporting you from mold design to mass production and final delivery.

Rapid Turnaround Times

Fast tooling and production to keep your project on schedule.

Quick Quote

Get accurate pricing and feedback within hours.

Engineering Support

Guidance from DFM to full manufacturing optimization.

Quality System

Strict inspections and process control ensuring reliable, consistent results.

An injection molding company with over 20 years of experience

RJC was established in 2002, in-house molding workshop is equipped with a full manufacturing system, including CNC machining centers, EDM, and wire cutting. We use certified steel grades such as P20, S136, and H13, and build molds to DME and HASCO standards. Our team provides complete mold design, manufacturing, testing, and pre-shipment verification. We also offer precision plastic injection mold manufacturing and global mold export services.

RJC operates an industrial zone of over 10,000 square meters in Shenzhen, China, and a 500-square-meter office and manufacturing complex in California, USA. RJC has passed the ISO9001, IATF16949, ISO 13485, FDA.

The CNC machining workshop has over 80 machines, the accuracy the accuracy is ±0.001mm. The molding workshop has over 50 machines from 80 tons to 650 tons to cover your multiple needs.

Four simple steps

Custom Prototypes and Parts Delivered on Time with Four Simple Steps